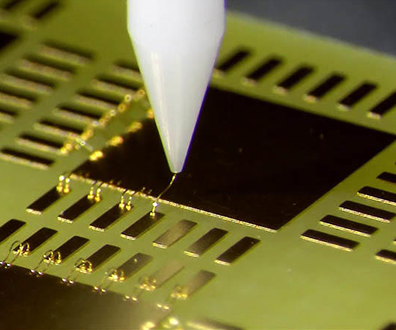

COB Services

Circuit board bonding is a way of bonding wires in the chip production process. COB bonding requires materials such as PCB (circuit board), Die (wafer), Silver glue (silver glue), AI wire (aluminum wire) and Epoxy (epoxy resin). Some materials may have substitutes, but in principle they cannot be without. The process will use die attach, wire bonding, dispenser, oven, and testing machines. The process flow of circuit board bonding: clean PCB - drop adhesive glue - chip paste - state wire - seal glue - test.

delivery time

Mass production lead time

Mass production lead time

| lead time Level | Lead Time (Wroking days,ex-factory | |

| Urgent(Day) | Normal(days) | |

| 100-1k | 2-3 | 2-3 |

| 1k-10k | 3-4 | 3-4 |

| 10k-100k | 4-5 | 4-5 |

| 100k and up | To be determined based on case | |

The above lead time is based on:

1.Conventional Material

2.All engineering consultations is confirmed

Our Newsletter

Sign up for industry alerts, news & insights.