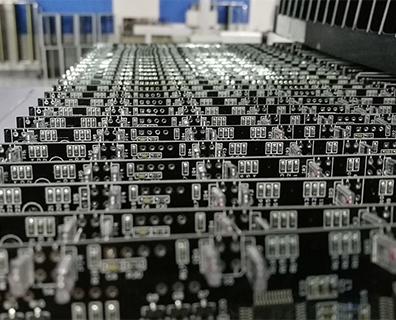

PCBs We Can Assemble a “prototype circuit board”

Min size: PCB whose width/length is less than 30mm should be panelized

Max size: single board 500mm*400mm | panel board 310mm*410mm

Layer Count: 1-40 layers (1-20 layers for mass production)

Copper Thickness: 1oz – 15oz

PCB Types: Rigid PCBs, Flex PCBs, Rigid-Flex PCBs, MCPCBs, Rogers PCBs, Ceramic PCBs, etc.

Surface Finishes: Lead/Lead-free HASL, ENIG, ImSilver, OSP, Gold plated.

Components We Can Assemble

SMT sizes: 01005, 0201, or larger

Fine pitch: 0.4mm or greater

BGA pitch: 0.35mm or greater

BGA Ball count: 2 – 50

WLCSP pitch: 0.35mm or greater

BGA, micro-BGA, POP, CSP, LGA package, Flip chip, Hard metric connectors, Cable & wire, etc.

Components Height: 0.1mm – 12mm.

Min. Components Spacing: 0.20mm for SMT parts, no specific demand for Thru-hole parts.

SMT Component Presentation

Bulk

Cut Tape

Tube

Tray

Partial Reel and Full Reel

Custom PCB Assembly Capabilities

Quick Turn

Prototype Quantities to Production Quantities

IPC III standard compliant

Single PCB Assembly and PCB Panel Assembly

Single and Double-sided PCB Assembly

SMT Assembly, Thru-hole Assembly, and Combo of SMT and Thru-hole Assembly.

Leaded Assembly, Lead-free or RoHS Compliant Assembly, and No-clean Process Assembly.

Consigned PCB Assembly, Partial consigned PCB Assembly, and Full turnkey PCB Assembly.

Mass production lead time

| lead time Level | Lead Time (Wroking days,ex-factory | |

| Urgent(Days) | Normal(days) | |

| 100-1K | 0.5-1 | 1-2 |

| 1K-10K | 2-3 | 3-4 |

| 10K-100K | 3-4 | 3-4 |

| 100K and up | To be determined based on case | |

The above lead time is based on:

1.Conventional Material

2.All engineering consultations is confirmed

Our Newsletter