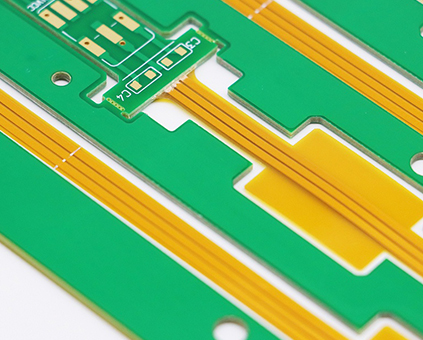

The Advantages of Rigid Flex PCB Technology

While this type of flexible circuit may be more expensive to design and produce, it does offer a number of important advantages. For instance, the reduced size makes it easier to fit more components into a smaller space. This can actually help to lower overall system costs. Additionally, because they require the need for fewer interconnects and related parts and components, these flexible circuit board can also prove to be more reliable and require less maintenance in the long run.

As with all types of flexible circuit boards, the rigid flex printed circuit boards will perform well in even the harshest environments, especially those featuring extreme heat. A rigid flex board is also easy to test, making it well-suited for prototyping.

Rigid Flex PCB Solutions of the Highest Quality

Currently, HonLynn Circuit has served companies in industries such as medical, telecommunications and manufacturing with our superior quality rigid flex PCB manufacturing services. We have an in-house quality control department to ensure your boards fabricated and assembled properly – we also guarantee the quality of all parts and components. Our engineers will even perform a Design for Manufacture (DFM) check at no

Mass production lead time

| lead time Level | Lead Time (Wroking days,ex-factory | |

| Urgent(hours) | Normal(days) | |

| 1、2L | 6-20 | 14-16 |

| 4L | 13-16 | 18-20 |

| 6、8L | 15-20 | 21-24 |

| 10L and up | To be determined based on case | |

The above lead time is based on:

1.Conventional Material

2.All engineering consultations is confirmed

Our Newsletter