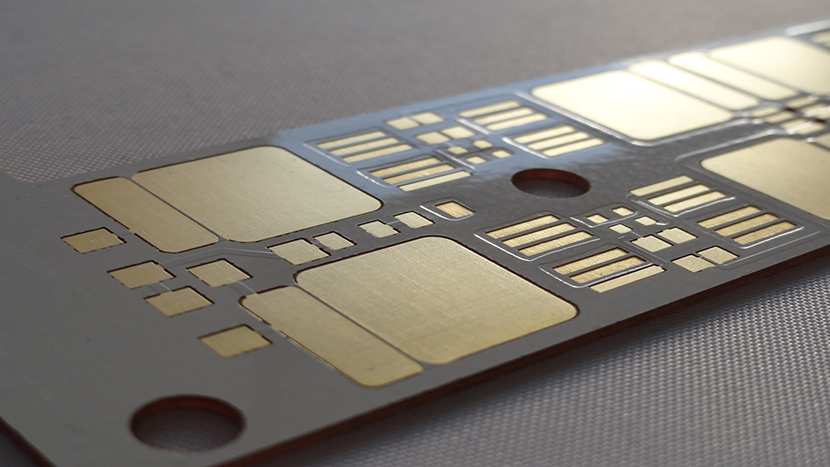

ENEPIG is essentially different from electroplated nickel gold and immersion gold:

Nickel electroplating, through the electroplating method, the gold particles are attached to the PCB board. It also known as hard gold because the adhesion is strong. Using this process can greatly increase the hardness and wear resistance of the PCB. Also, it can effectively prevent copper and other Metal diffusion, and meet the requirements of hot compression welding and brazing.

Immersion gold is a chemical reaction that causes gold particles to crystallize and attach to the PCB pads. Because of its weak adhesion, it is also called soft gold.

In the PCB prototype process, ENEPIG, nickel electroplated gold and immersion gold all belong to the surface treatment process. The difference is that nickel electroplated nickel is done before the solder mask while ENEPIG and immersion gold are done after the solder mask.

In summary, compared with other surface treatment processes, the main advantages of the ENEPIG process are:

(1) Avoid the risk of black pad: Compared with ENIG, the ENEPIG process introduces a palladium layer between the nickel layer and the gold layer, which can effectively prevent the diffusion and migration of nickel, avoid the corrosion of electroless nickel-phosphorus alloys, and also effectively inhibit the oxidation of the nickel surface layer and prevent the welding process of the occurrence of black pad.

(2) Long-term reliability of the coating: The ENEPIG coating has high stability, and there are no obvious defects generated by SEM after aging treatment, indicating that the coating has long-term reliability under normal use conditions.

(3) Lead-free soldering: The ENEPIG coating can form solder joints with high soldering strength with lead-free solder (Sn-Ag-Cu) to achieve the same soldering strength as leaded (tin/lead) solder. It has longer service life and can meet the requirements of lead-free soldering.

(4) High reliability of welding and wire bonding: More than ten years of application and research have shown that ENEPIG surface treatment can obtain good welding bonding and wire bonding performance.

(5) Reduce component size and increase line density: Because the ENEPIG process has excellent solderability and wire bonding performance, it can provide higher flexibility and freedom for circuit design, especially high-density circuit design. The flexible application of various packaging processes can gradually reduce the size of electronic components and increase the density of circuits.

(6) Low cost: The introduction of the palladium layer can greatly reduce the thickness of the gold layer. In recent years, the average price of palladium is only 1/3 of the average price of gold. After calculation, when the thickness of palladium plating and gold plating is the same, the use of palladium plating saves 60% of the cost and has better solderability and welding reliability, so more substrate and PCB manufacturing companies hope to use ENEPIG technology to replace immersion gold and electroplated nickel gold.

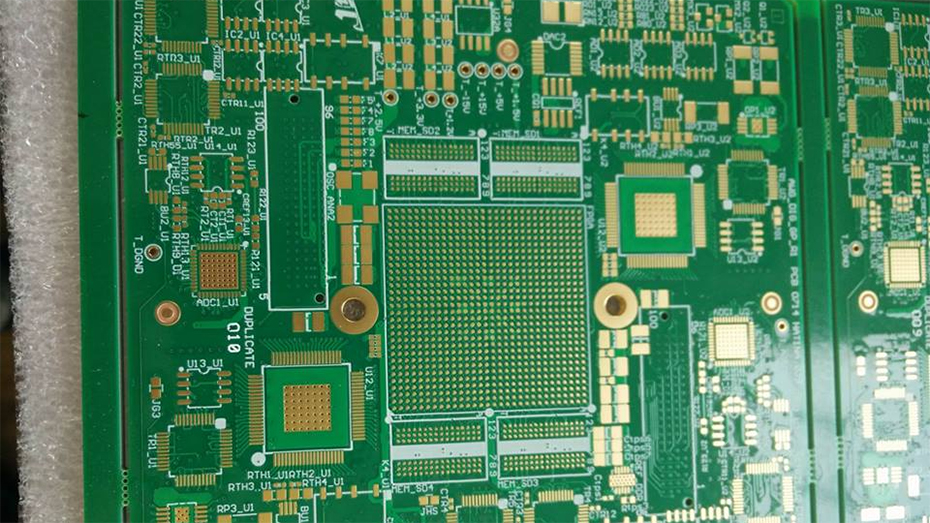

Mass production lead time

| lead time Level | Lead Time (Wroking days,ex-factory | |

| Urgent(Days) | Normal(Days) | |

| 1、2L | 3-7 | 8-10 |

| 4L | 7-10 | 12-14 |

| 6、8L | 9-14 | 15-18 |

| 10L and up | To be determined based on case | |

The above lead time is based on:

1.Conventional Material

2.All engineering consultations is confirmed

Our Newsletter